MENUMENU

- Home

- Company

- Services

- Products

- Turnkey solutions

- News

- CONTACT

- +49 6181 70221-0

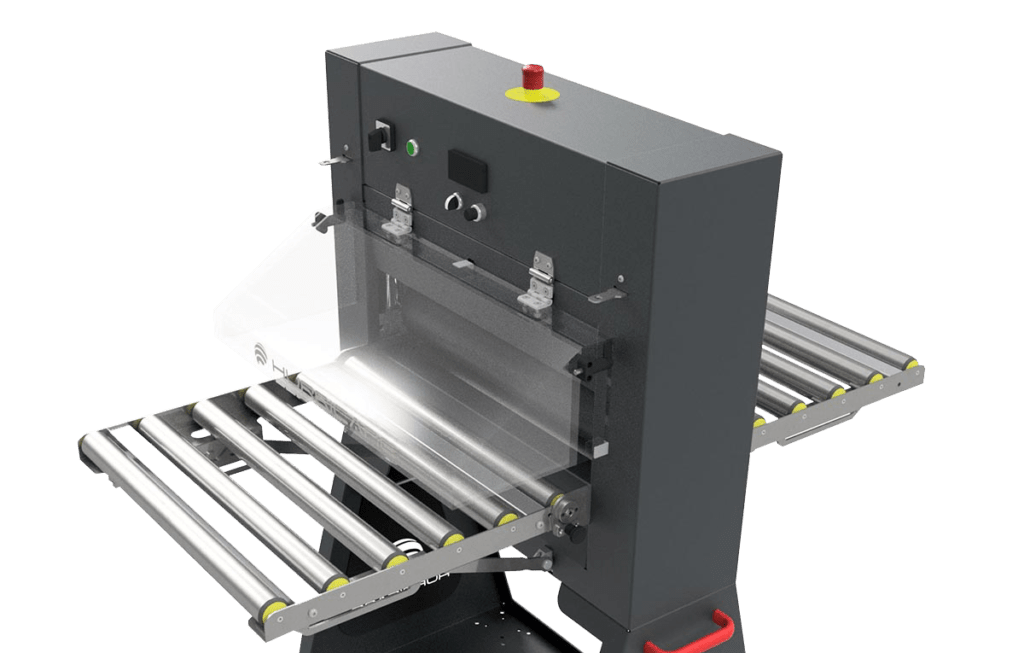

The innovative and material-friendly impregnation systems are ideally suited for the even distribution and complete soaking of the resins into the liner for trenchless sewer rehabilitation up to DN1200.

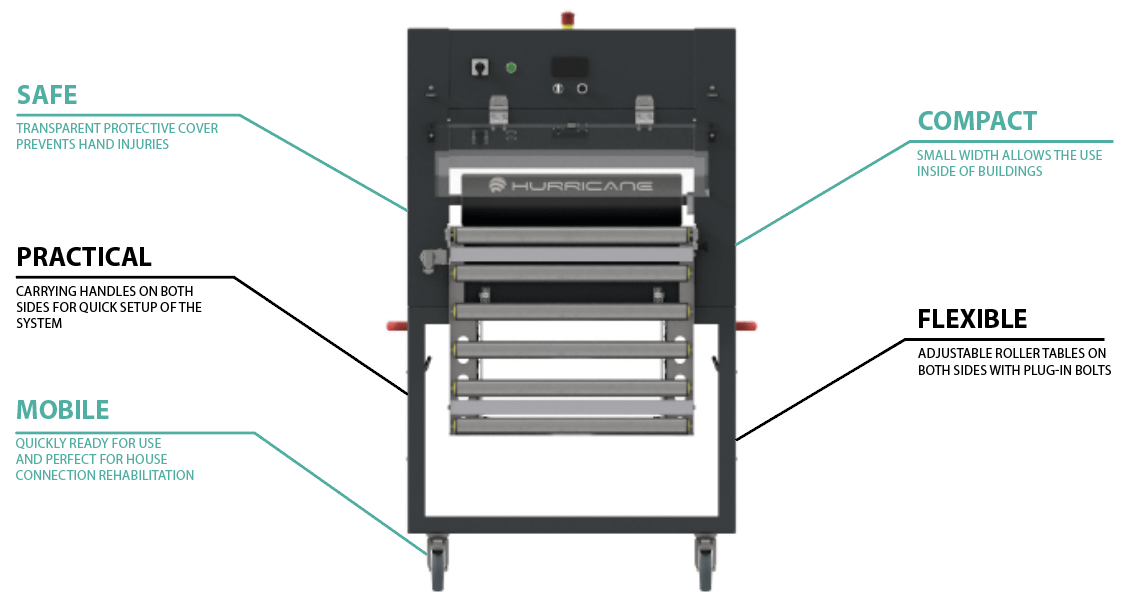

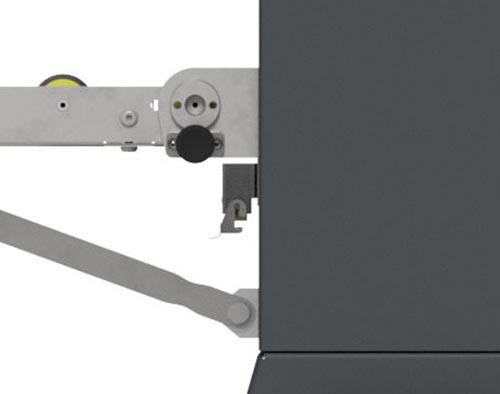

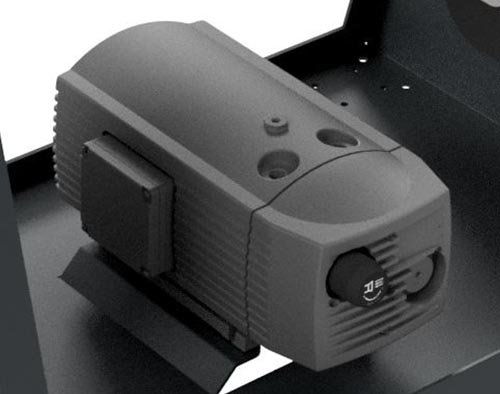

The Hurricane® impregnation system Maxi up to DN300 is a comfortable, user-friendly solution in a new design. Due to exact stepless adjustment of the roller table and the synchronously driven rollers, the liner can be impregnated smoothly, gently and evenly – without any manual force.

Innovative solutions at the cutting edge.

Our impregnation systems are available as mobile version or as fixed, permanent installation. The units are made of stainless steel or aluminum. The drive or propulsion can be realized manually or electrically. Roller conveyors are usually folded out or mounted on both sides of the unit, depending on the size of the system. Large versions can be optionally connected to PLC resin mixing systems.

The perfect tool for daily use. Developed and manufactured 100% in Germany:

| NAME | ORDER NUMBER | DIMENSIONS (LXWXH) | Max. liner dn | ROLLER TABLE | VERSION |

|---|---|---|---|---|---|

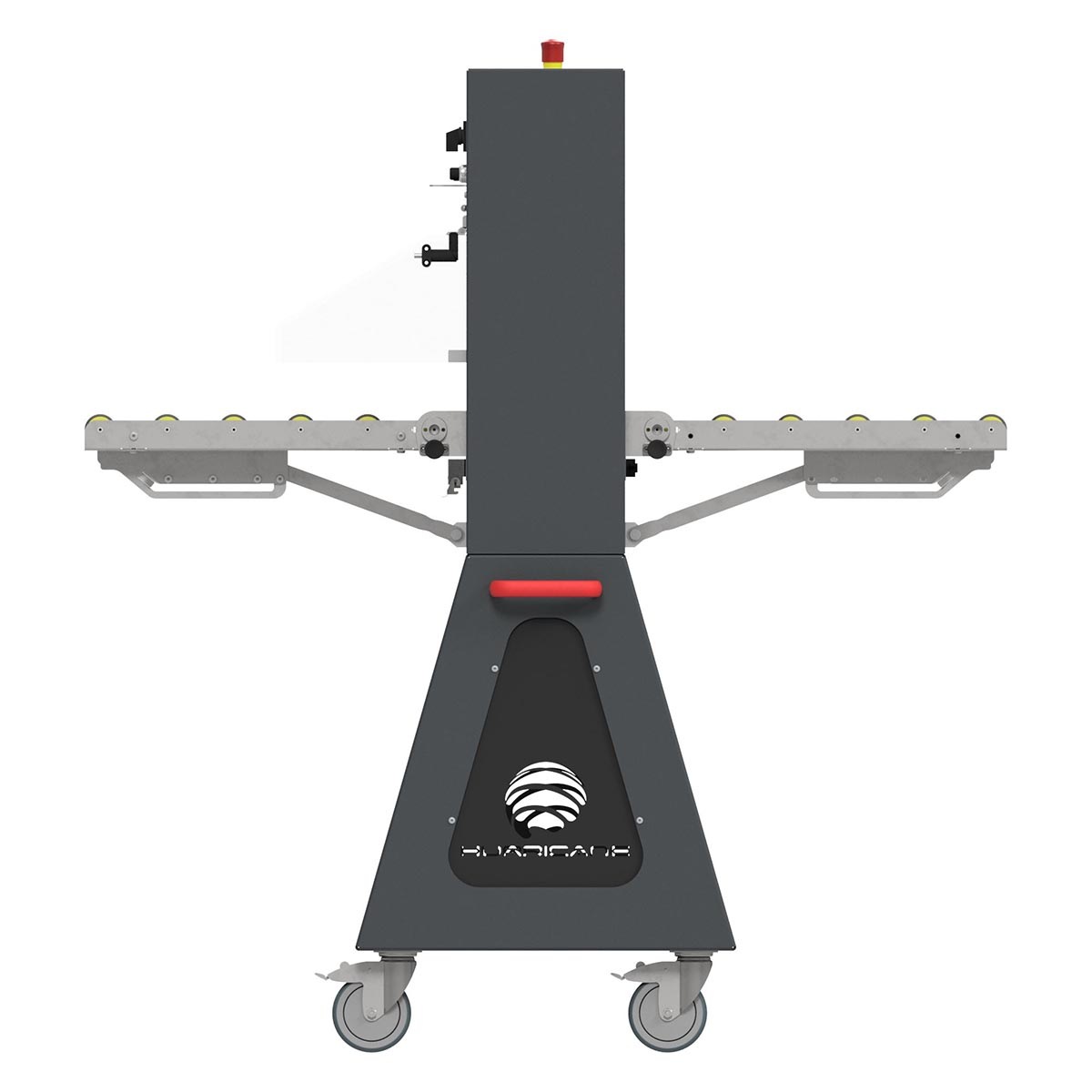

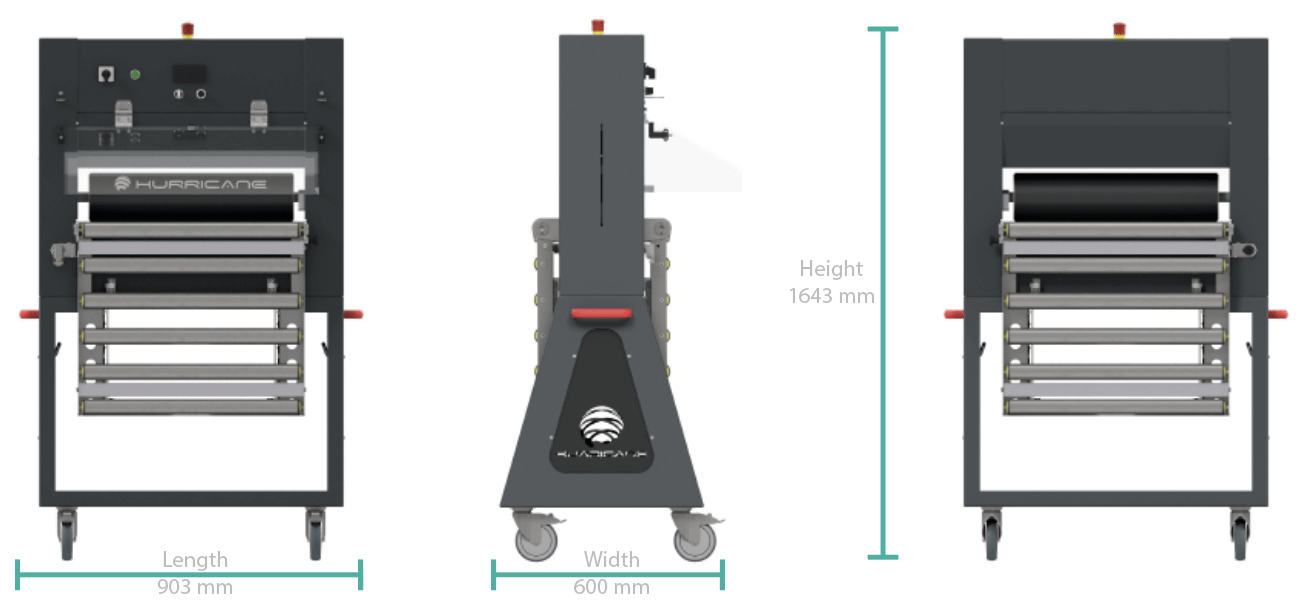

| Impregnation System Maxi | 28100015 | 903 x 600 x 1643 mm | 400 | both sides, foldable | mobile version |

| PROTECTIVE COVER | ROLLER DRIVE | WEIGHT | HEIGHT ADJUSTMENT |

|---|---|---|---|

| yes | electric | 179kg | digital |

Hurricane Trenchless Technologie GmbH

Wilhelm-Röntgen-Str. 6

63477 Maintal