MENUMENU

- Home

- Company

- Services

- Products

- Turnkey solutions

- News

- CONTACT

- +49 6181 70221-0

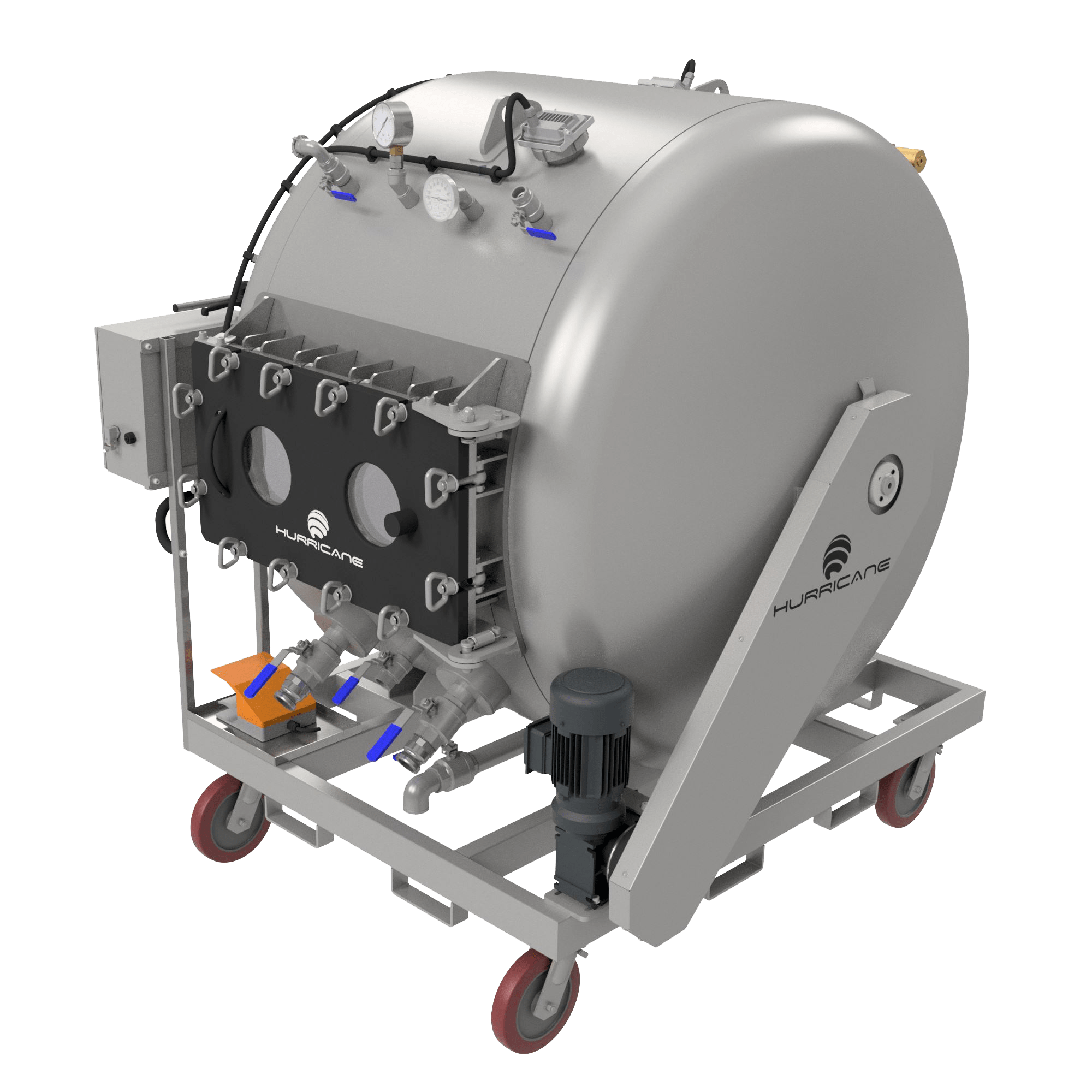

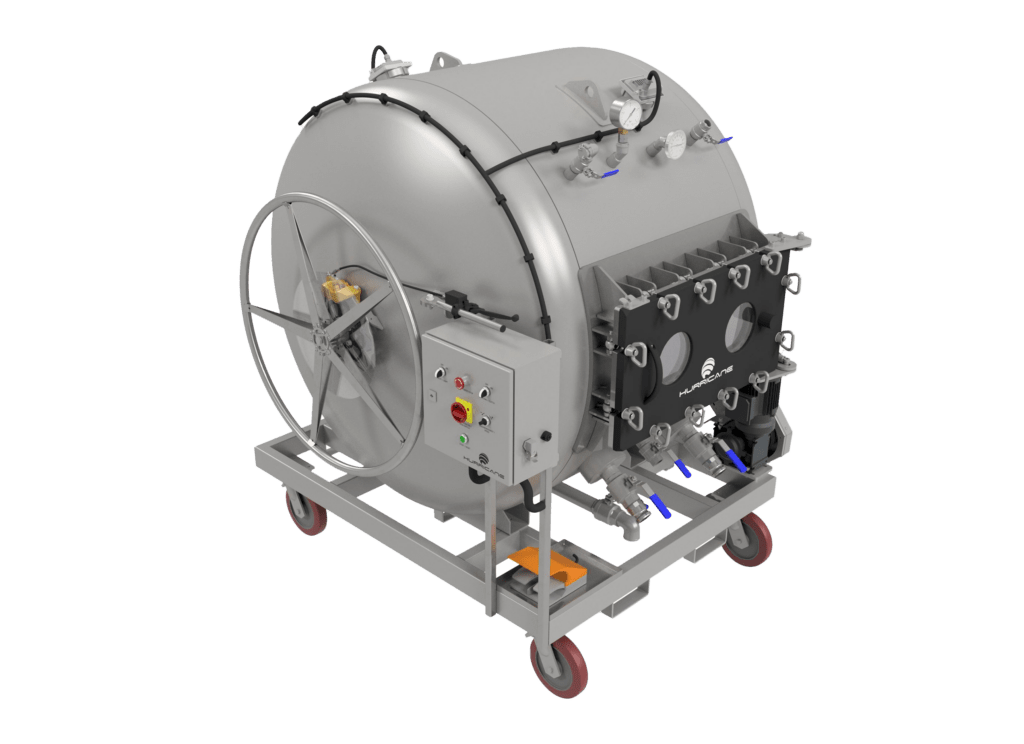

With the help of the Hurricane inversion drums, the flexible liner can be easily, safely and quickly inserted into the sewer that needs to be rehabilitated. The resin-impregnated hose (liner) is wound onto the drum axle with a control rope and inversed into the open-ended or closed-ended sewer by compressed air. The inversion pressure and the inversion speed are constantly controlled via the control elements on the inversion drum.

After the impregnated liner has been inverted, the heating medium hot water or steam is introduced via the inversion drum to accelerate the curing process by means of thermal energy. This results in the creation of a new pipe in the old pipe.

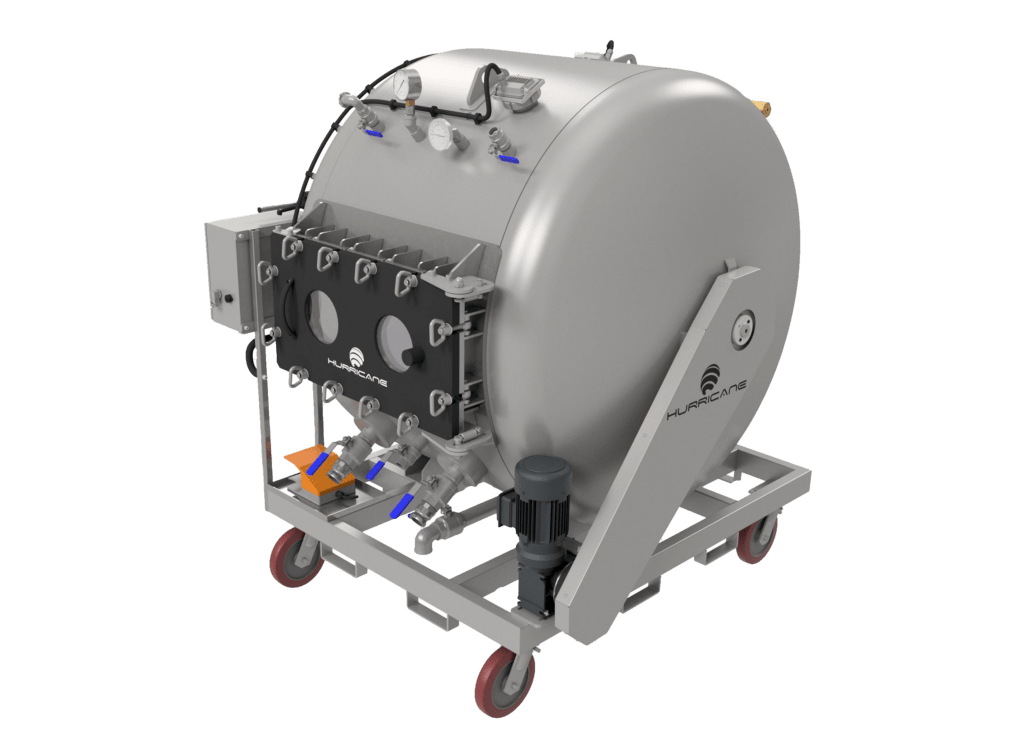

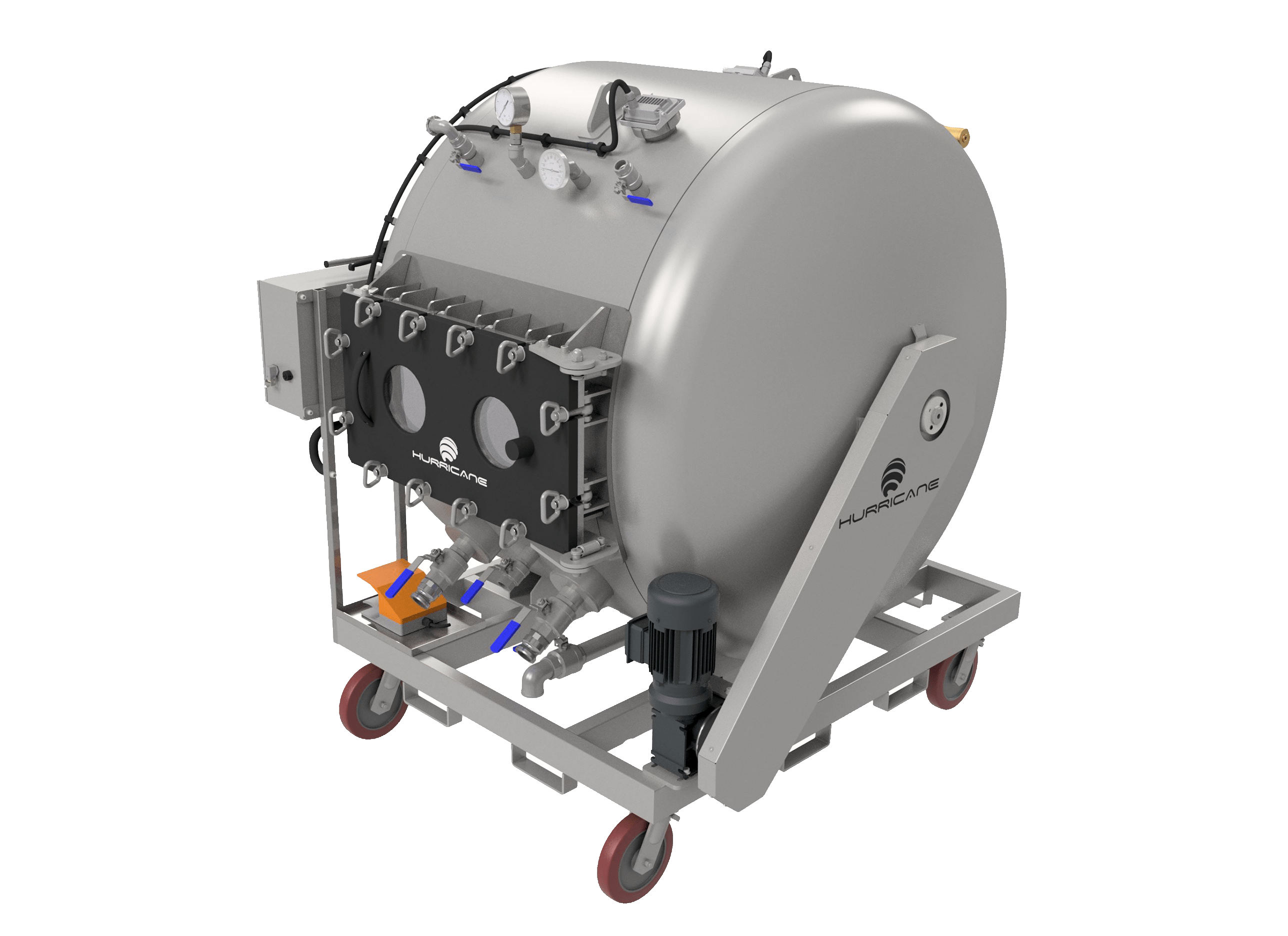

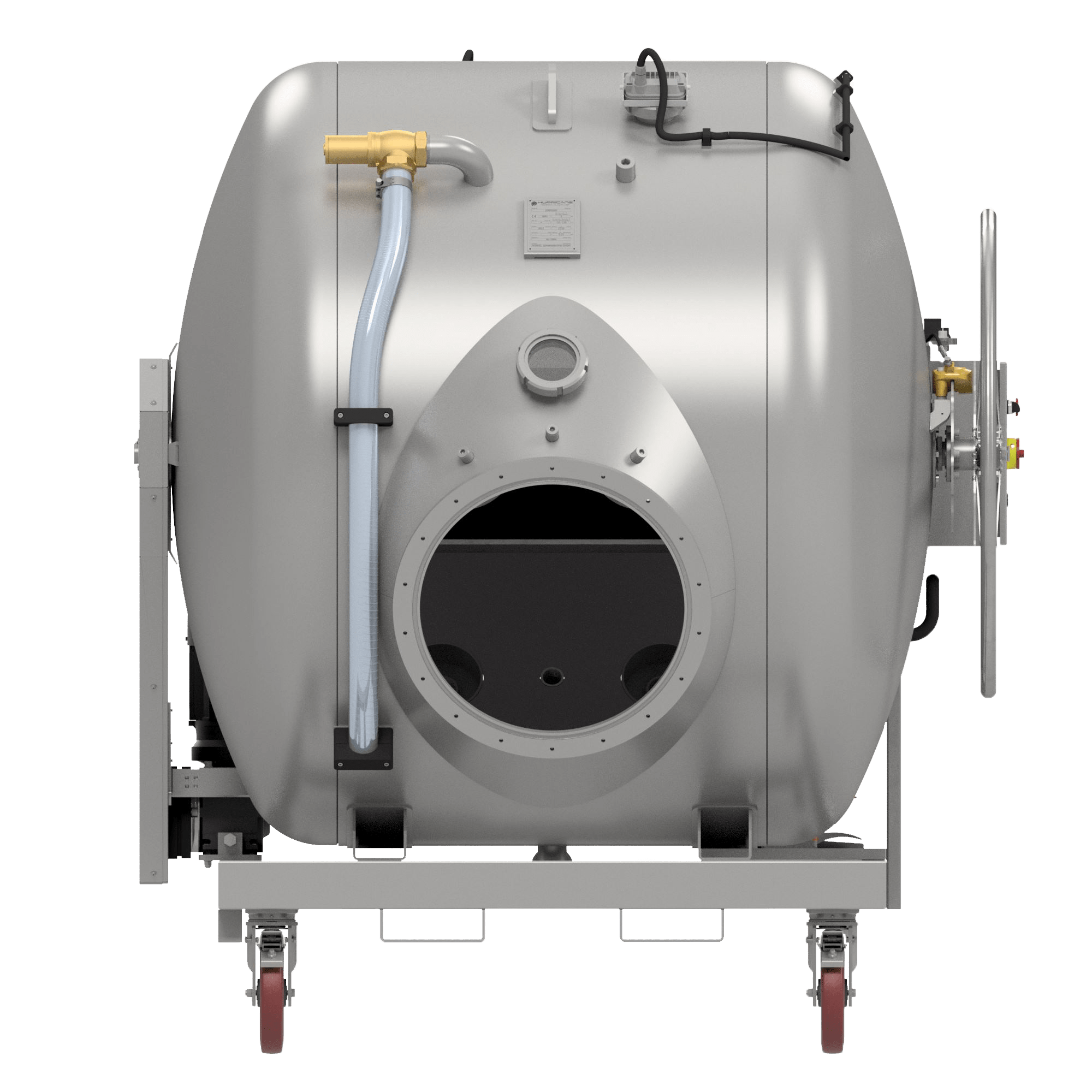

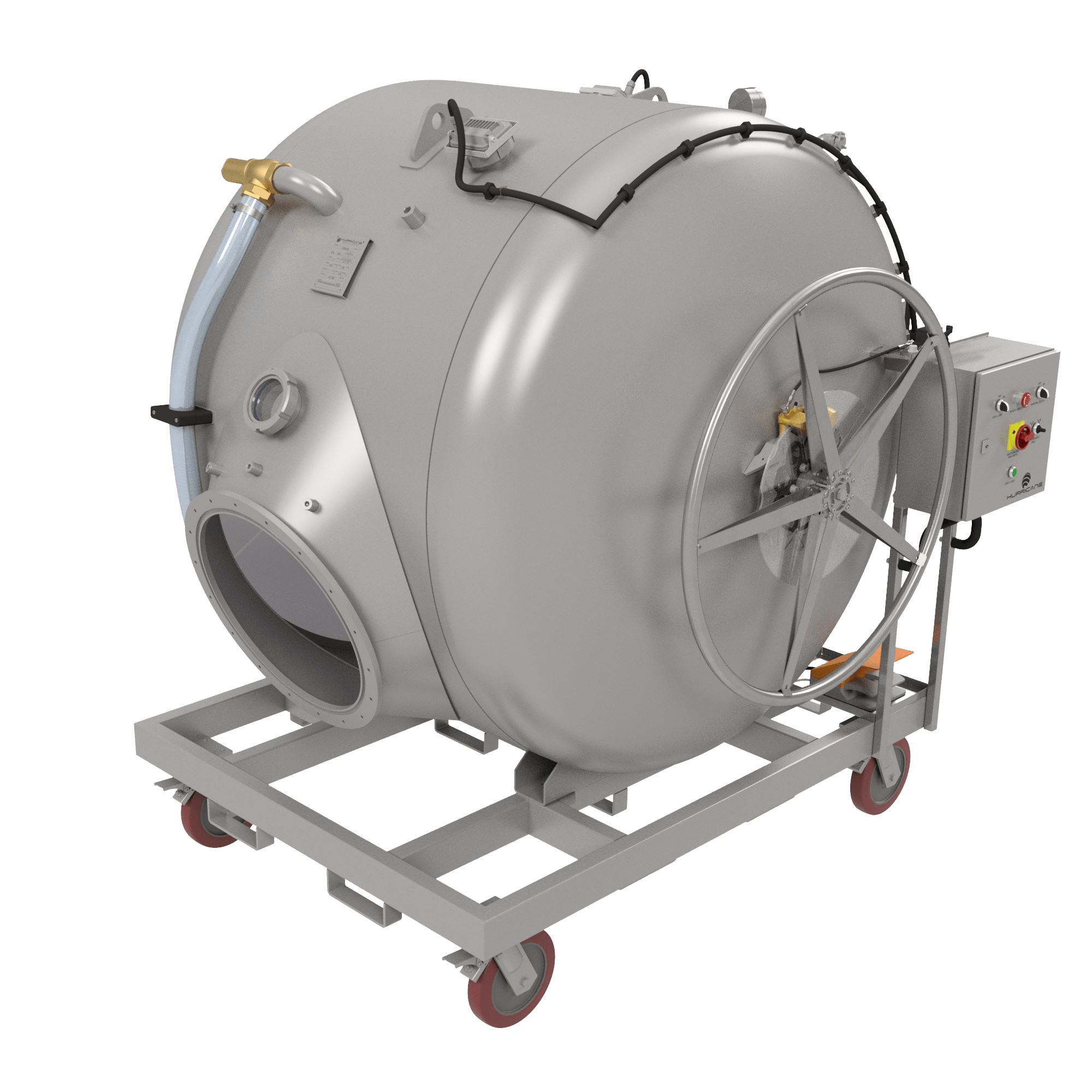

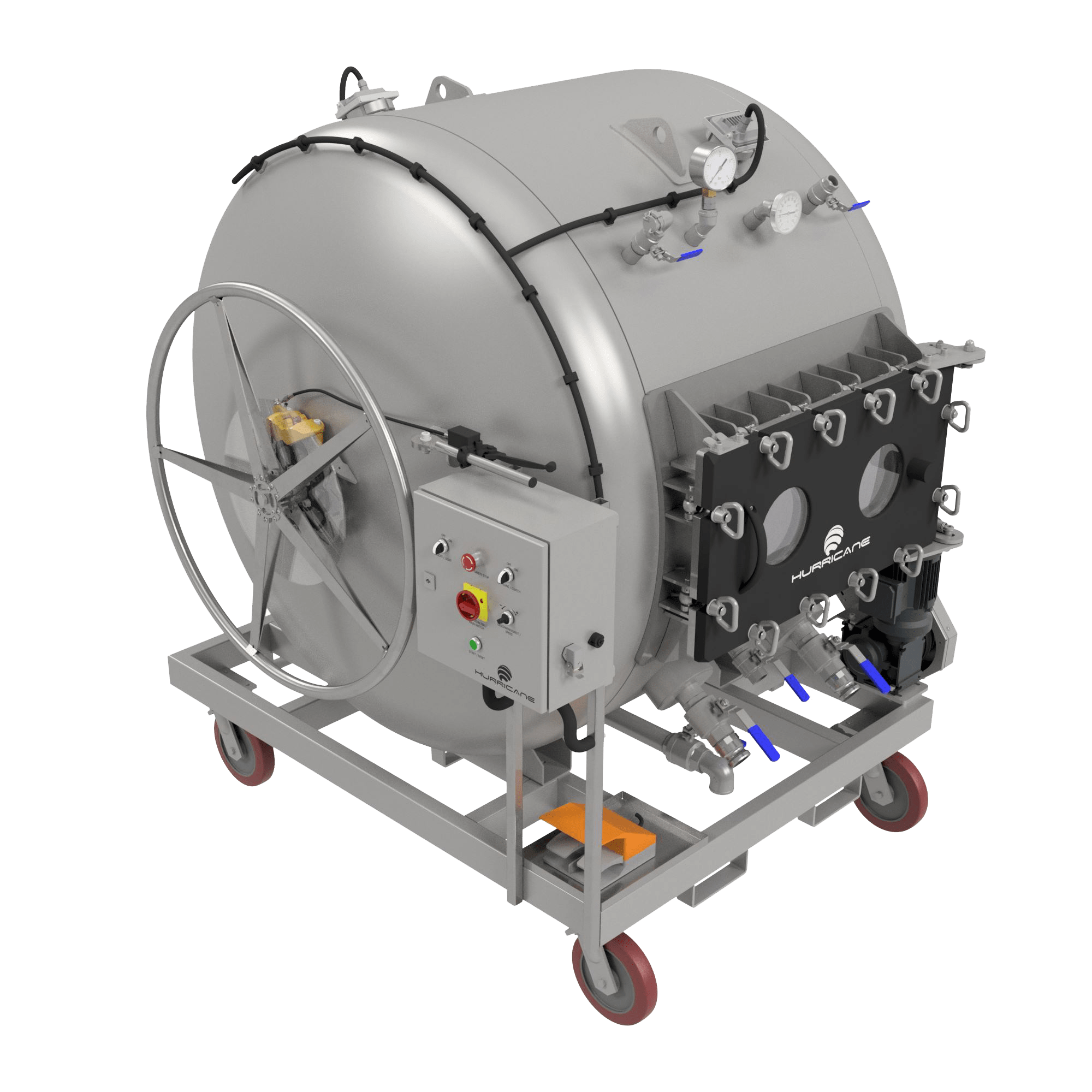

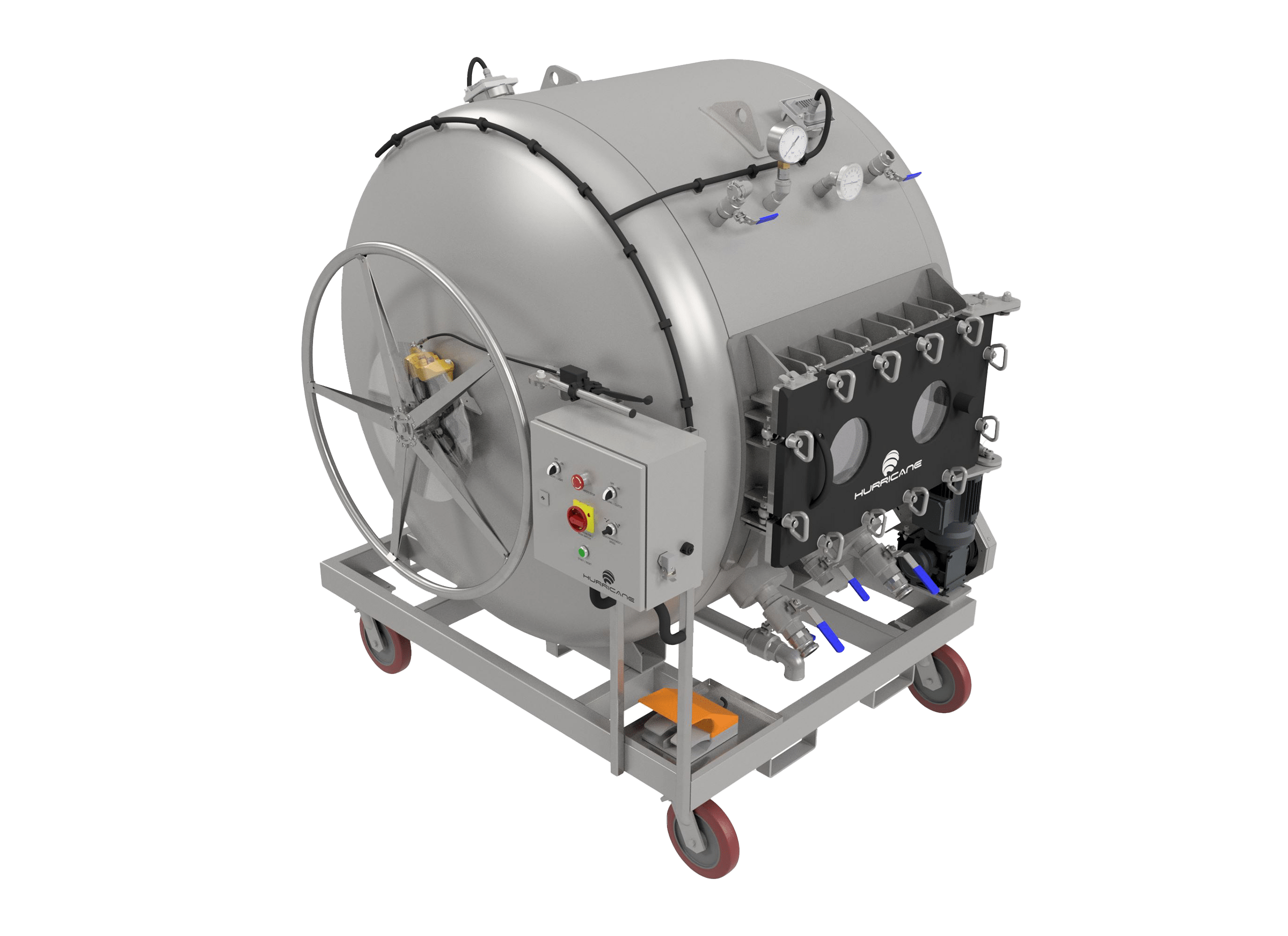

Mobile Hurricane® Thunder Drum 1600 inversion unit on stable frame construction and with side loading for inserting the liner in the main sewer and side inlets up to DN500.

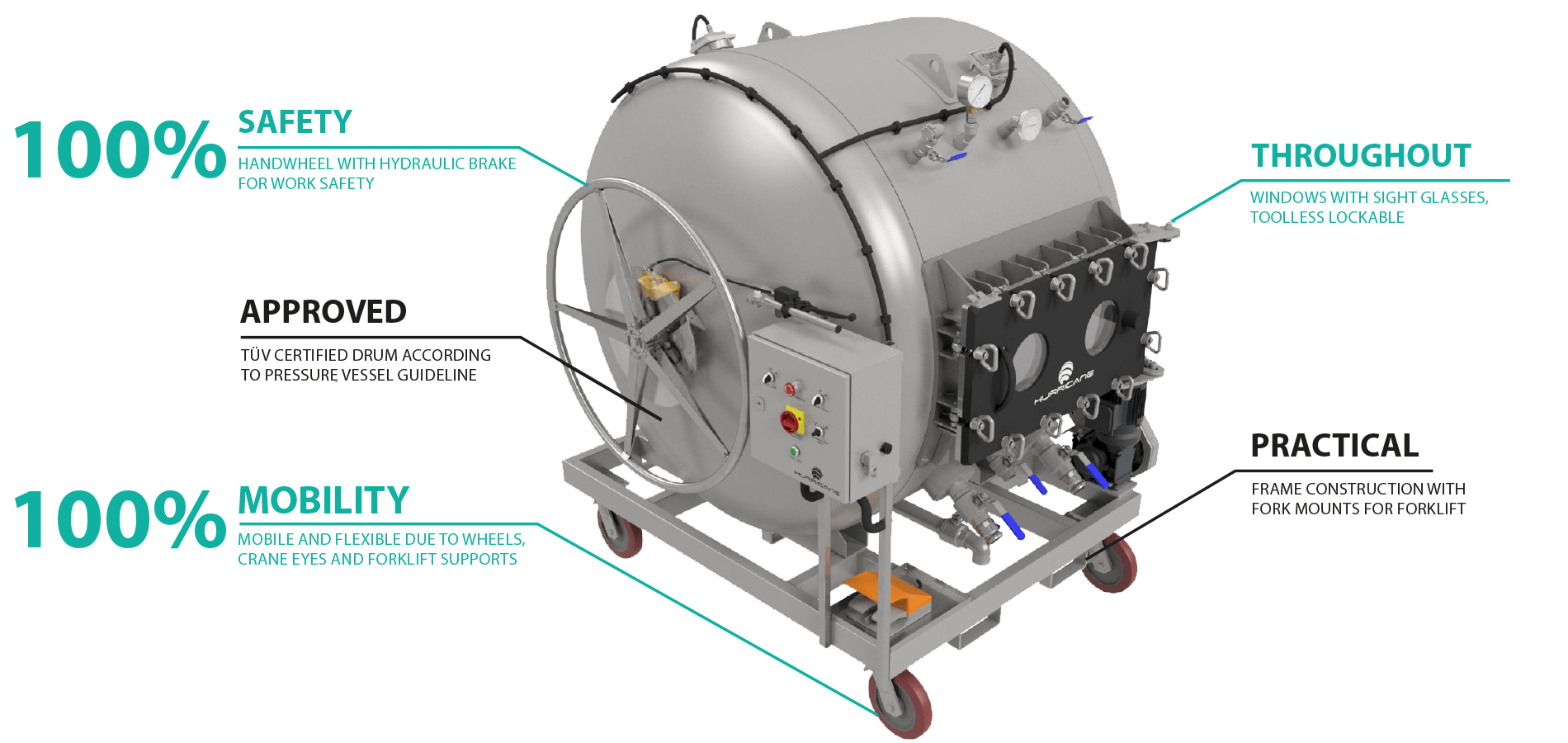

Optimized motion control and wheel safety by means of locking device

Drum body with newly developed substructure (base)

Stainless steel construction, glass bead blasted, coated

8“ Storz locking system on the hopper

Large and ergonomic hand wheel with disc brake

Electric drive with control box

All necessary fittings and connections

Suitable for curing with hot water and steam and light

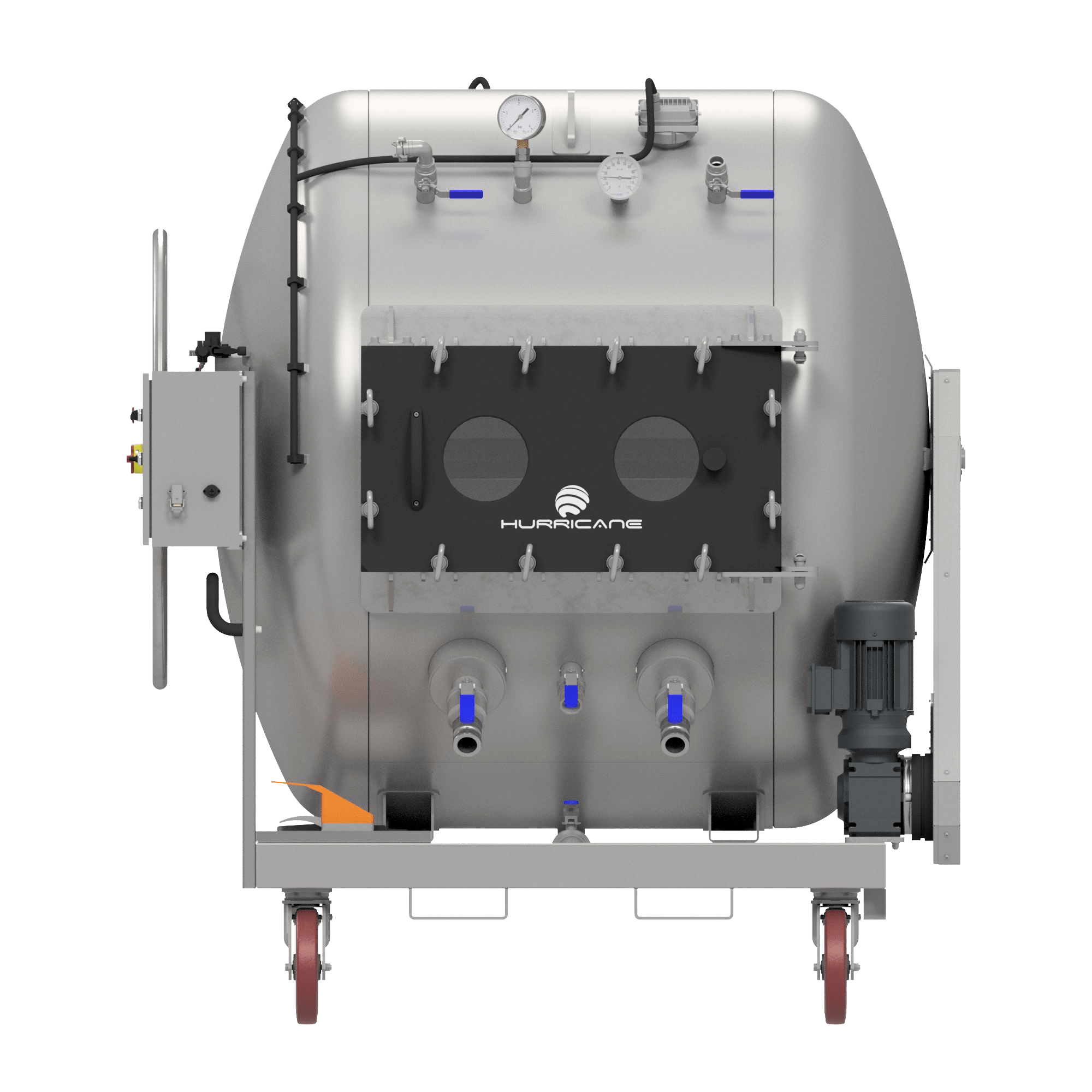

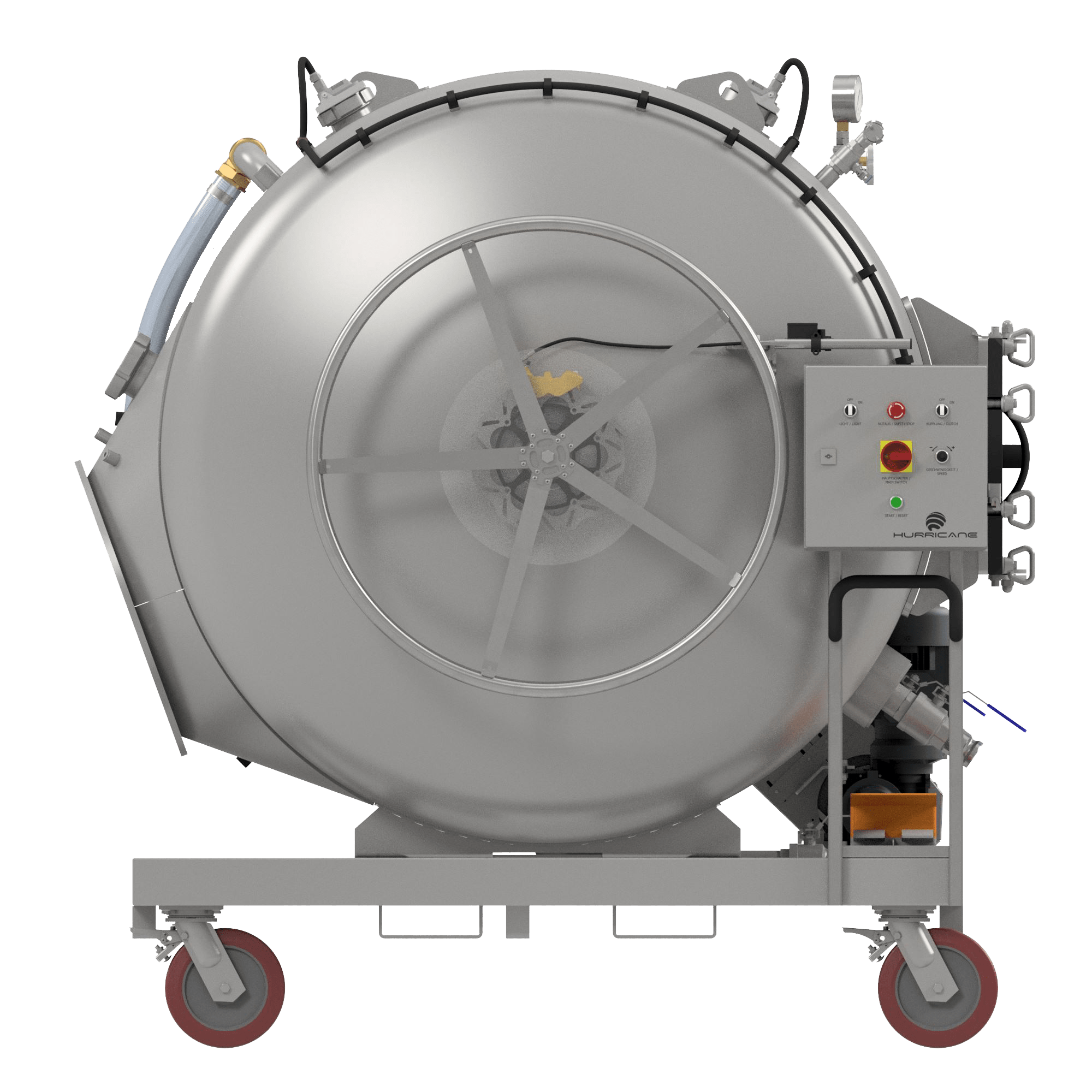

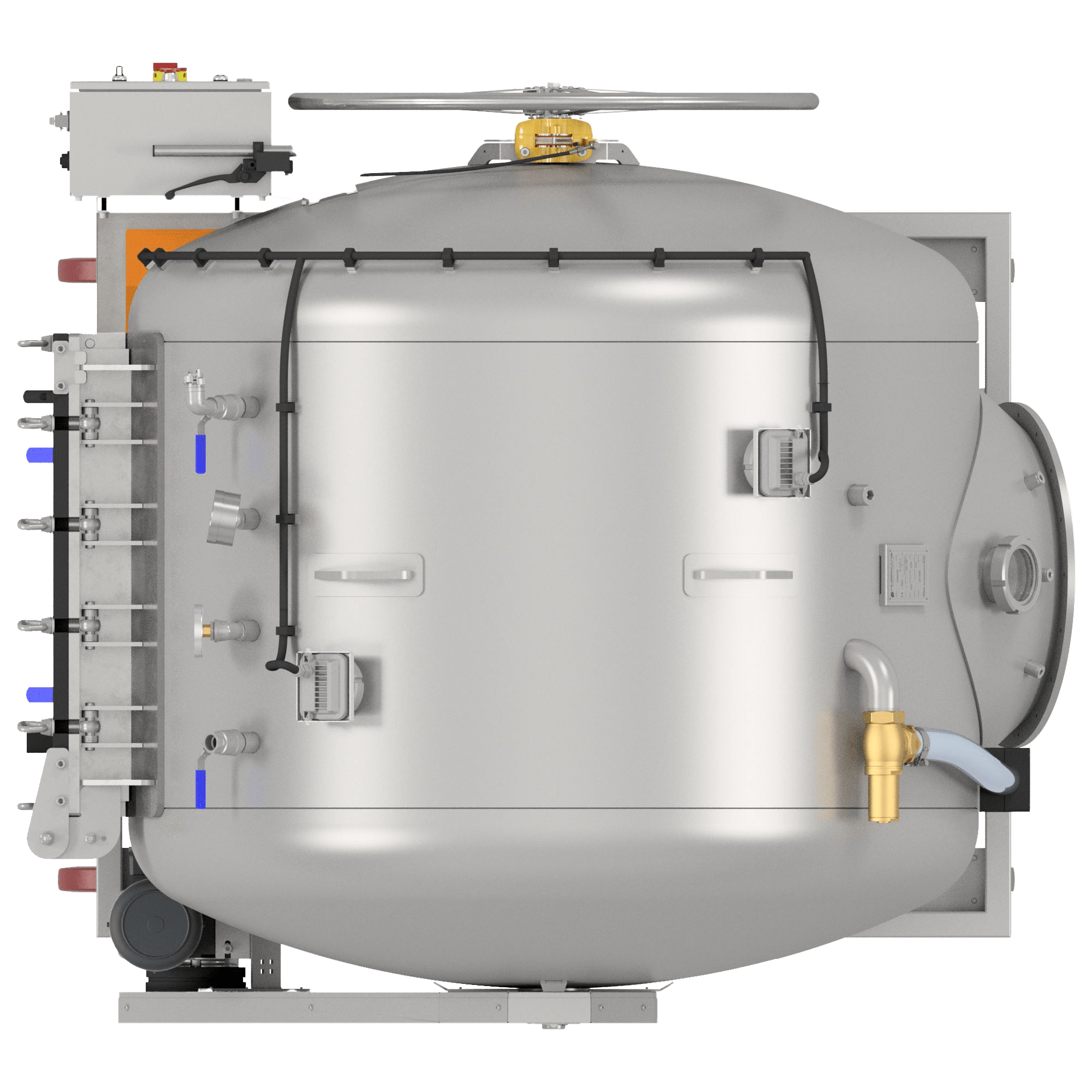

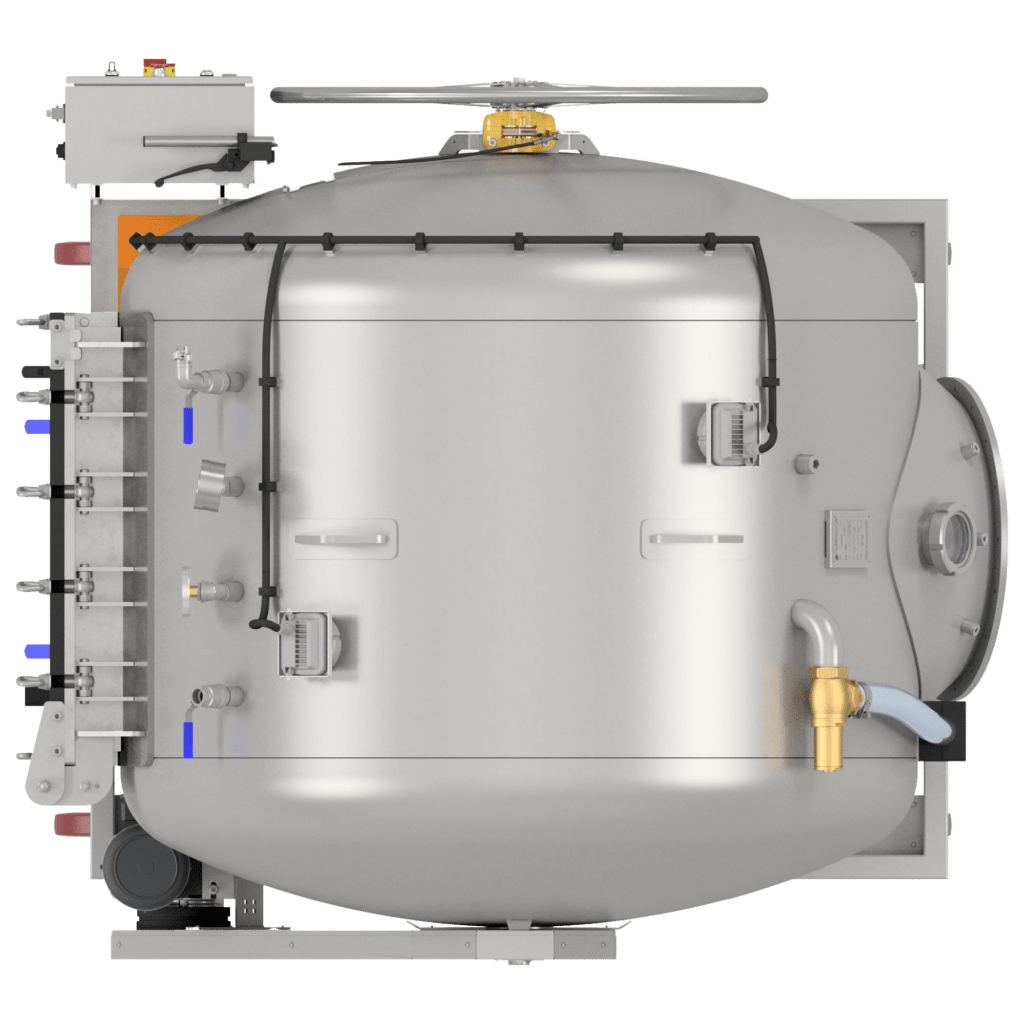

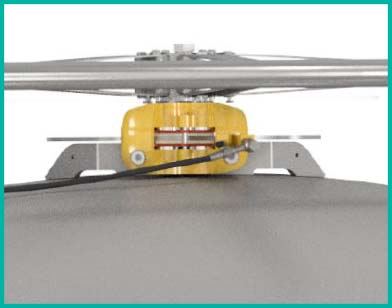

Disc brake

on handwheel

Forklift receptacles

and rollers

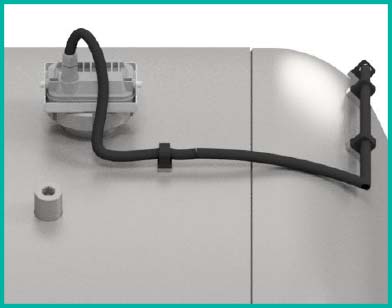

LED

Interior lighting

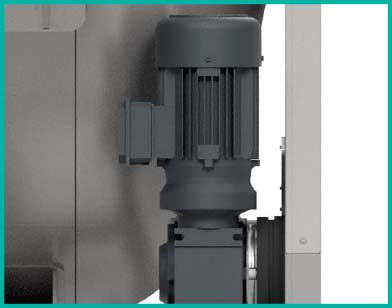

Electric motor

for axial rotation

Control box

with controls

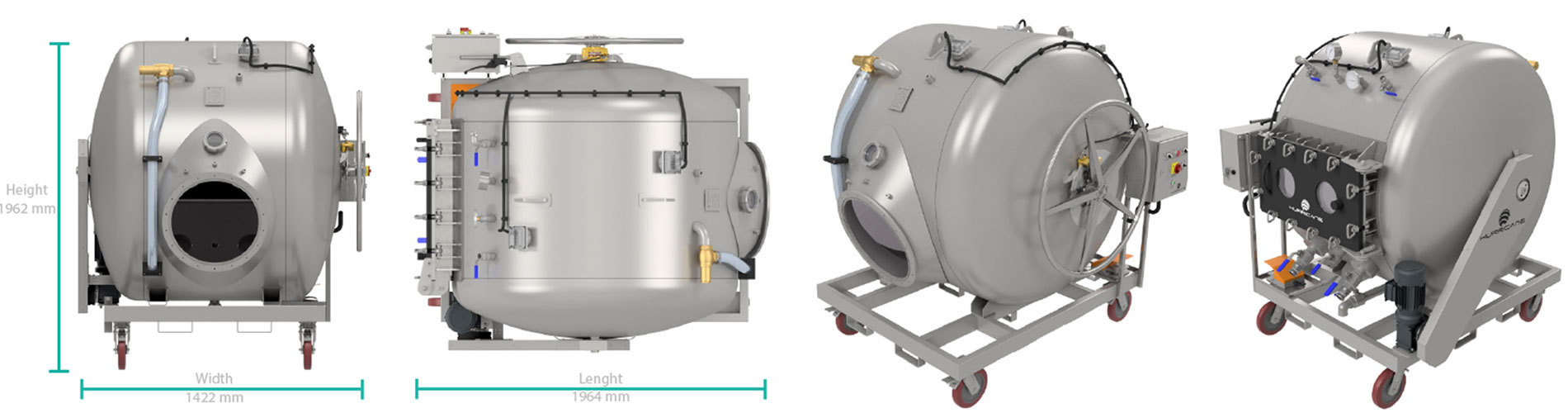

| NAME | DRUM-Ø | DIMENSIONS (WXLXH) | Control window | Connection | Max. Pressure | Curing method | Max. Temperature | Weight | Safety valve | Max. Liner Lenght |

|---|---|---|---|---|---|---|---|---|---|---|

| Hurricane® Thunder Drum 1600 | 1600mm | 1422 x 1964 x 1962 mm | 400 x 750 mm | 8“ Storz | 1,5 bar | Air, steam, hot water, light | 100°C | 660 kg | 1,5 bar | DN100/4mm = 200m DN150/4mm = 150m DN200/4mm = 125m DN300/4mm = 100m DN400/4mm = 100m DN500/4mm = 75m |

Hurricane Trenchless Technologie GmbH

Wilhelm-Röntgen-Str. 6

63477 Maintal