MENUMENU

- Home

- Company

- Services

- Products

- Turnkey solutions

- News

- CONTACT

- +49 6181 70221-0

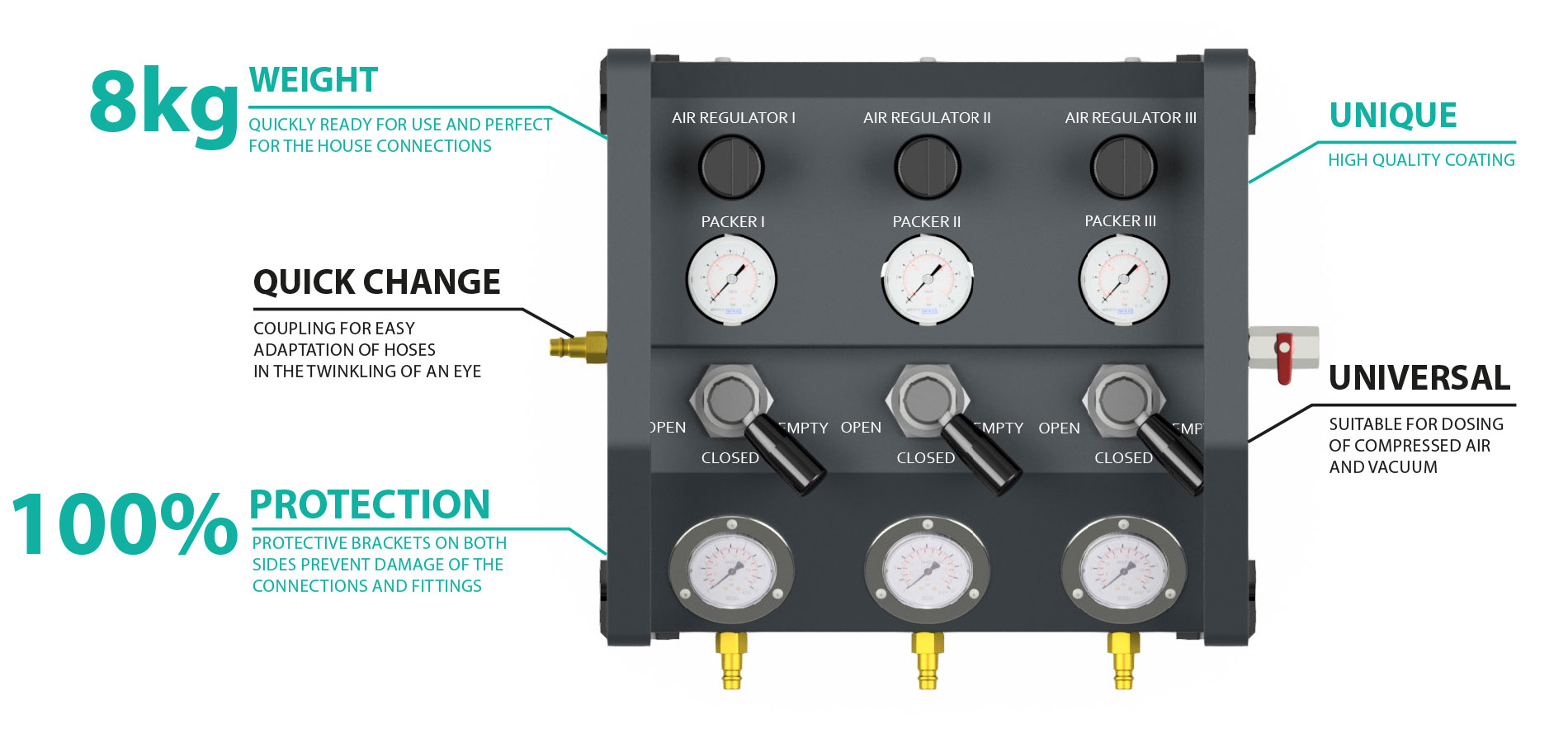

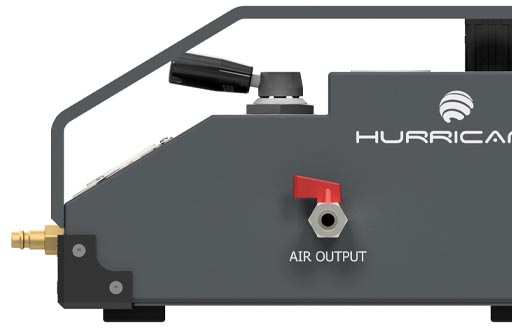

With the help of the Hurricane® PBX series, short liner rehabilitation can be carried out easily, safely and quickly. A short liner impregnated with resin is applied to a rehabilitation packer and pulled/pushed to the damaged area of the pipe. By means of the PBX box for compressed air metering, the packer is inflated in a controlled manner and constantly pressurized with compressed air for the predefined period of time. The pressures can be regulated for the respective connection via the control and monitoring elements of the pressure box.

Optionally, the timer function can be used to observe the curing times. Once the time has been reached, the pressure is removed or slowly reduced and the rehabilitation packer is removed from the pipe. Because the pressures can be controlled separately, work can be done in parallel (at the same time) or even time-shifted to increase productivity on multiple installations.

The optional vacuum function of the PBX pressure box also allows the use of top-hat packers.

The Hurricane® PBX series specially developed for demanding and efficient partial pipe rehabilitation (short liners, hat profiles, etc.). PBX pressure boxes are mobile, self-explanatory control units for compressed air and vacuum dosing of rehabilitation packers. Increased productivity on the construction site – installation of up to 4 short liners at the same time possible.

The perfect working tool for daily use. Developed and manufactured 100% in Germany:

PRODUCTIVITY INCREASE ON THE CONSTRUCTION SITE

CONTROLLED COMPRESSED AIR DOSING

ROBUST AND DURABLE

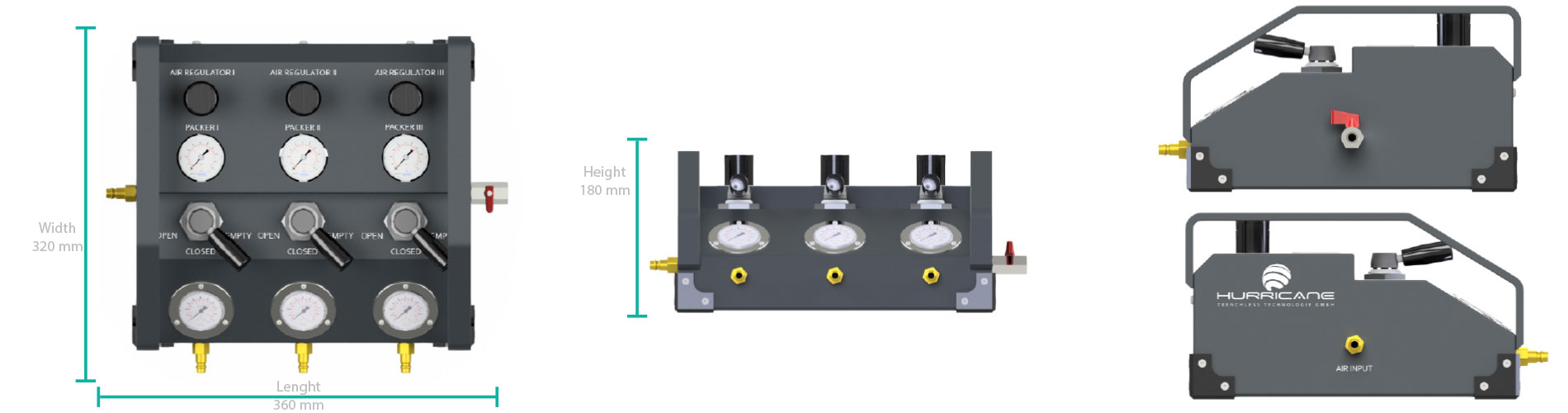

| NAME | ORDER NUMBER | DIMENSIONS (LXWXH) | TIMER FUNCTION | CONNECTIONS |

|---|---|---|---|---|

| Hurricane® PBX3 | 28100011 | 360 x 320 x 180 mm | optionally | 5 Quick couplings |

| MAX. PRESSURE | PRESSURE REGULATOR | INPUT MANOMETER | OUTPUT MANOMETER | WEIGHT | DOSING |

|---|---|---|---|---|---|

| 10 bar | 3 | 3 | 3 | 8kg | Compressed air (pos.) Vacuum (neg.) |

Hurricane Trenchless Technologie GmbH

Wilhelm-Röntgen-Str. 6

63477 Maintal